Nowadays, a 3D printer is pretty much common among hobbyists, there are now many kinds of 3D printers, you can choose which one could print the fastest, big volume, low maintenance, sophisticated, etc. People can also make a living by opening a 3D printing service from their garage/basement.

But, most likely, for people like me with a tight budget and got lazy to do all the maintenance and etc. Well, I guess it’s easier to just order it from any local 3D printing service I could find.

A 3D printing service could help your model get printed rather quickly, mostly in 3-4 days your printed model will get delivered to your doorstep. Some services also provide a click and order through their website making less interaction with customer service, and some small business services also required a model inquiry through chat messenger before ordering.

I prefer the second one because I can talk with the expert/customer service and ask their opinion whether my 3D print setting (layer thickness, infill, etc) is good enough or need some modification on the model. After all the setting is agreed upon and calculated then they will come up with the price.

Don’t look only for a single 3D printing service, most of the time I was looking at several 3D printing services I could find, and then I compare each of them before making a purchase. Before ordering, there are things that you need to consider regarding the material, the volume of the model, the usage of the model, etc.

How big is the model?

Common 3D printers can only print a medium/small model (20x20x25)mm, (220x220x220)mm, 300mm, etc and for a larger model, you’ll going to need an industrial 3D printer. So, you’ll need to ask whether your model fits their 3D printers or not, some services could also provide a tricky way to align your model diagonally or lift up the model with additional support so the model can fit with the printer dimensions. I don’t recommend this way because the final result will lose some precisions.

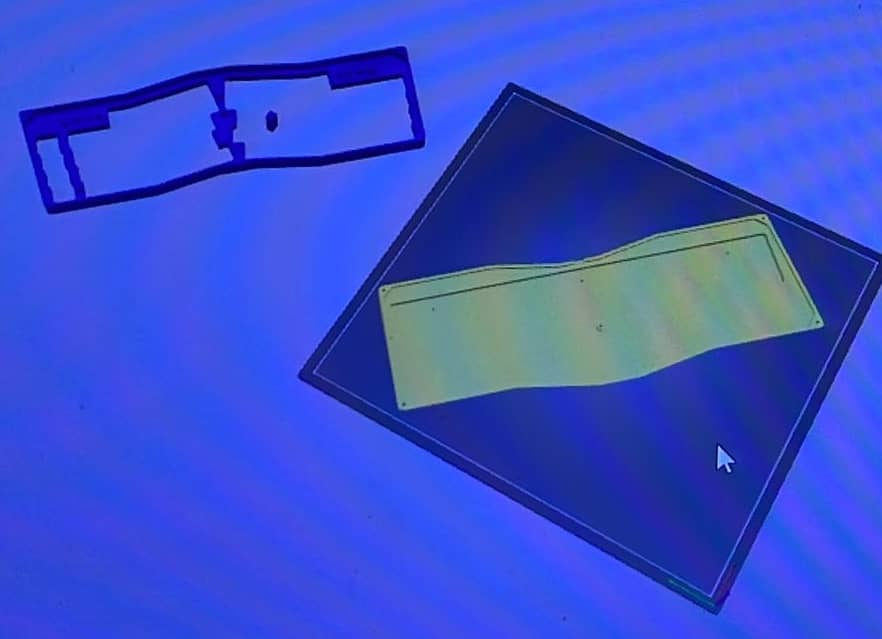

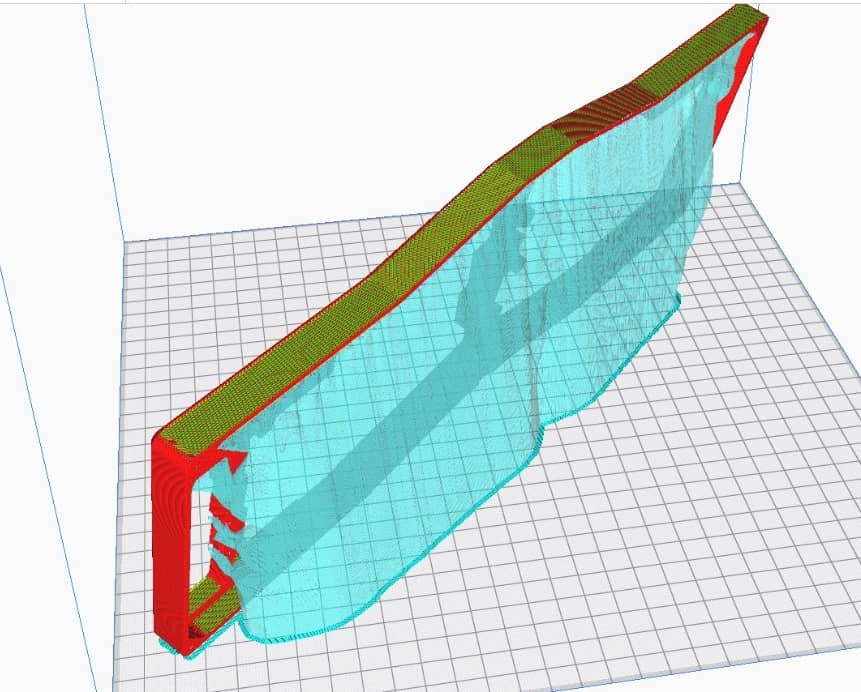

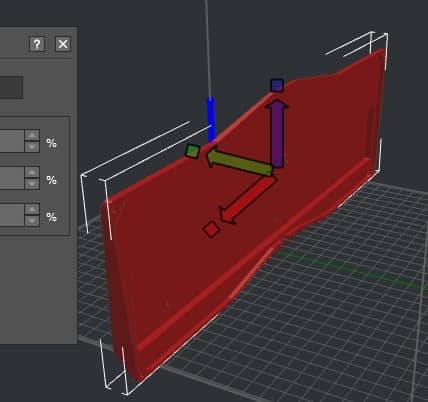

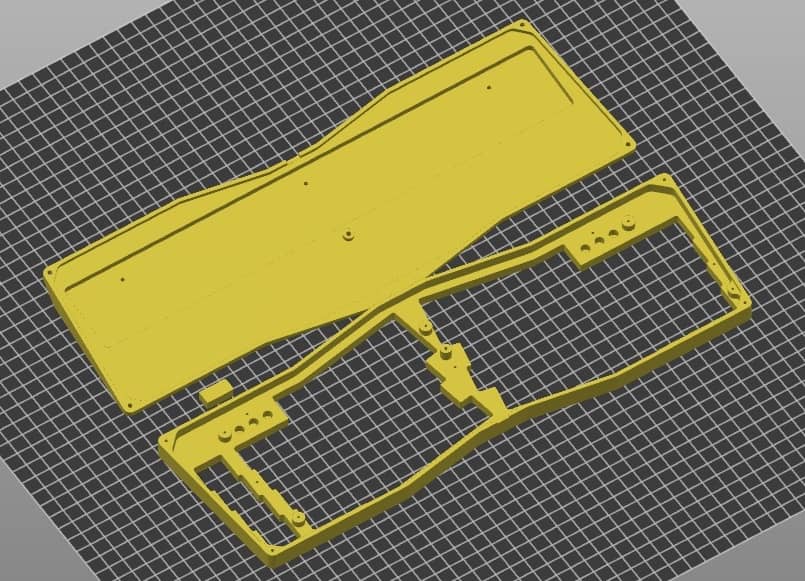

Usually, after inquiring they will send you some images that show you how your model fits the printer. These are some examples, I went to some 3D printing services and I compare each of them, all the vendors are given the same file.

Vendor A

They cannot align the model horizontally because it won’t fit the printer, so they place it diagonally. The cons are there will be diagonal thin lines around the model instead of horizontal, for some people this could be annoying, the bed is also too tight so you might lose some precision. The pros if the model is lying down on the bed position that means it will have less support and less cost for the material, much cheaper.

Vendor B

The 3D printer is a lot smaller than Vendor A. The model can’t be placed lying down on the bed position. So, they need to make the object in a standing position and create a lot of support for this (the layer with cyan color) It’s possible to lose some stability when printing the model and lose some precision. You’re also going to pay for the support that will cost you 30% more, not to mention you have to remove and clear the support. Most likely, I’m going to pass this vendor.

Vendor C

As you can see, the model is too large for the printer, even though it might fit if you put it diagonally as vendor C did but they wouldn’t recommend it because of the same reason. So, I would pass this vendor also, and thank you for being honest.

Vendor D

There is a lot of space on the bed and all the models can fit altogether, this is perfect and might be the one that I’m looking for, a wide bed, no extra support, and all the models fit the bed. So this must be the winner.

How much stiffness does the model needs?

The stiffness of your model needs depends on the material that you’re going to use and also the setting of wall thickness and the infill, I can only find 3 materials from my local vendors ordered from the stiffest,

PLA >>>>>> ABS/ASA >> PETG

PETG is the less stiff material and more flex than the other two, you would want to have a lot of infill and wall thickness for this material. ABS/ASA is the same, but I will go with the ASA. PLA is way stiffest among those two.

Does the model need to have impact resistance?

This is rather important because it will define whether your model could break easily upon impact or maybe when you drop the model. Ordered from the most resistance,

ABS/ASA >>>>>> PETG >>>> PLA

ABS is way more resistant to impact despite the stiffness. if you’re making a protection tool I would definitely go with this material. PETG is a bit more resistant than PLA this might be because PETG has a flexible material.

Is it for Outdoor/Indoor use?

IMO this is related to whether your model needs to be heat resistant or not. If you’re going to use the model outdoor, then you need to have a sunproof material. Ordered from the most heat resistant,

ABS/ASA >> PETG >>>>>> PLA

As you can see that PLA kryptonite is heat, even if the heat is only 30°C it will bend or deform the model, you really need to keep away the model from the sunlight. Do not ever use PLA for outdoor activity.

PETG is good enough to withstand the sunlight heat, it would resist the heat up to 70°C. Good enough for outdoor activity the cons is PETG is actually the less stiff material.

ABS/ASA is the strongest against heat, it’s way strong as it could stand the heat up to 95°C, between ABS and ASA, most likely the ASA has UV protection so if you print with white material it wouldn’t get yellow easily.

Conclusion

I did my research from my own experience and also from any articles and youtube videos I could find. I kinda summarize all the things I found in this article, hopefully, this might help you to find a perfect material for your model depending on the usage and the budget of course.

Tips

- Don’t use PLA for outdoor usage, if you did use PLA, don’t get exposed to the sunlight. I might use this material for figurines, bathroom appliances, and indoor decoration.

- ABS can also be used for indoor/outdoor usage, heat resistant, impact-proof, and stiff enough, I would definitely go for this one for any usage.

- PETG could be an alternative to ABS, durable enough but it’s a bit more flexible, you might want to set the wall thickness and infill more than 50%.

- For good print quality, I would choose PLA, PETG, and then ABS. ABS could get worst from printing small detail, PLA has the best print quality among others.

- If you’re tight on a budget, PLA is cheaper compared with PETG and the most expensive is ABS/ASA.

- If possible, get your model printed with less support, using too much support will get the price higher than you expect and it’s quite a hassle to clear all the support.